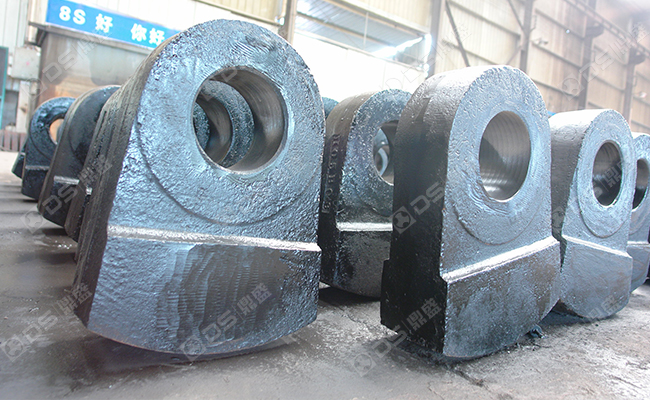

The CRUSHER HAMMER is the core part of some crushers, whose quality is close related to the service life of spare part. Therefore, the crusher hammer should have not only high hardness and wear resistance, but also higher toughness and higher impact resistance.

The main factors affecting the crushing ability of the crusher hammer include the hardness, composition, viscosity and humidity of the material, the final output size and so on.

①The particle size and hardness of the crushed material. The larger the size of the material block, the higher the hardness, the more difficult it is to crush. The hardness of crusher hammer should be high enough.

②The viscosity and humidity of the material. If the water content of the material is too high, it is easy to stick, causing material accumulation, aggravating the wear of crusher hammer.

③The power and speed of the crusher rotor. They are related to not only the production capacity, but also related to the impact hardening degree of some crusher hammer. If the high manganese steel hammer has a good impact hardening degree, its service life will be prolonged; the slower the rotor speed is, the smaller the crushing capacity of the high manganese steel hammer is.

④The final discharge size. The smaller the required final size of crushed material, the slower the crushing speed and the greater the crusher hammer wear.

⑤The basic composition of the material. The fine powder or mud contained in the raw material will affect the crushing ability of the crusher hammer, because these fine powder and mud is easy to stick, which will affect transportation and accelerate the wear of the hammer.

⑥ Some uncommon material (such as iron blocks) entering the crushing cavity will have a great impact on the crusher hammer, causing the hammer to wear faster, even broken and scrapped.