Raw materials: various construction, renovation and demolition waste of buildings, roads, and bridges, such as bricks, tiles, wasted concrete blocks, etc.

Production capacity: 20-1000t/h

Applications: recycling C&D waste generated in construction renovation and demolition projects, producing recyclable products for building, construction and bridges etc.

Delivery: 25-50 working days

First, the collected construction and demolition waste need to be sorted to separate the impurities out. After that, the materials like concrete, bricks and tiles etc. would be sent into the vibrating screen, which is divided into two parts by the primary screening equipment. The coarse materials on the screen are sent to the special crusher for further crushing. The massive iron material can be removed by a magnetic iron remover in this process. The crushed materials can also be divided into different purposes and different particle size inorganic mixed aggregates. For example, in a static C&D waste processing complete plant in China, the recycled C&D waste is processed into 0~5mm, 6~10mm, 11-20mm, 21-30mm gradation aggregates for special needs occasions.

Advantages of Static C&D Waste Processing Complete Plant

1. Convenient for integrated management with a comprehensive production and living facilities system, and able to complete environmental protection better, which can effectively control production costs;

2. One-time installation and debugging enables continuous production, which saves the adjustment time spent on moving the site;

3. There are sufficient spare parts warehouse to meet the needs of continuous production.

Through classification, grading, crushing and screening of static C&D waste processing complete plant, recyclable aggregates that can replace natural sand and gravel are produced. Part of the aggregate is used as the company's deep processing raw materials with the company's self-produced cement together, to produce ready-mixed mortar, cement mixtures, wallboards and components. And the rest part can be sold as commodity aggregates to concrete mixing stations and ready-mixed mortar stations, Highway foundation backfilling, etc. The air-selected powder and soil are supplied to building materials manufacturers to produce blocks and garden departments as greening soil.

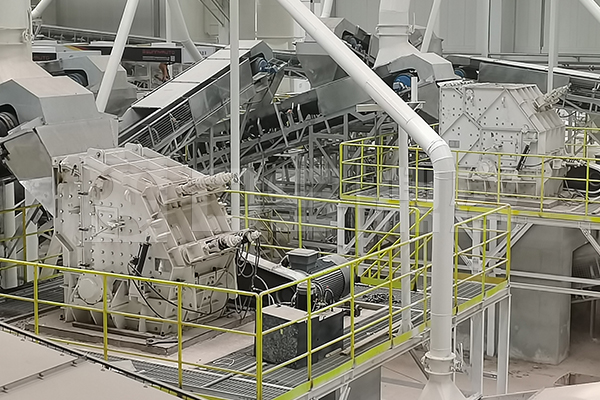

With more than 20 years experience of equipment designing and manufacturing in C&D waste recycling field, DSMAC has cooperated with many clients to help them design and install the static C&D waste processing complete plant for construction and demolition waste recycling. The main equipment of static recycling plant are shown as below.

AF European Impact Crusher DPF Construction Waste Crusher