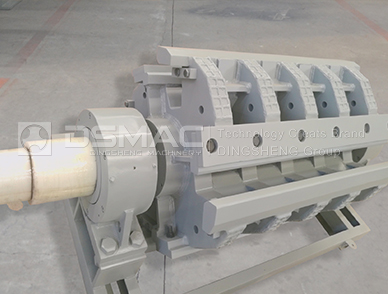

In order to meet the needs of crushing large size stone and ore, the high-speed rotating IMPACT CRUSHER ROTOR with a plate hammer has to be of sufficient weight and smooth operation. No matter when replacing new plate hammer or repairing old ones, the balance of the rotor should be paid attention, otherwise it will affect the normal operation of the equipment.

1. Consequences by Impact crusher rotor imbalance

1) It will generate a large inertia force and inertia moment, which will cause unstable operation of the equipment;

2) It will cause large vibration of the rotor to generate additional dynamic load, making the bearing temperature rising too high, and even causing crack damage to some parts further service life to be shortened.

2. Reasons for impact crusher rotor imbalance

1) The rotor itself has quality problems since the manufacturer does not make production strictly in accordance with standards;

2) Severe and uneven wear causes that the center and barycenter of the rotor body is not in the same position, resulting in the uncertainty of static balance and dynamic balance;

3) Unstable feeding makes the rotor stressed unevenly.

3. Solutions to impact crusher rotor imbalance

1) Perform rotor balance test before putting into production;

2) Feeding evenly and stably, avoiding intermittent interruptions;

3) When replacing the hammer, make sure to install it correctly, and it is better to change all of them or symmetrical ones.

Long-term working under harsh conditions can increase bearing wear on the impact crusher rotor. With the current technical level, once the rotor fails to work, the cost of repair and replacement could be terribly high, and the production will suffer serious losses, too. Therefore, in the daily operation, we must keep our eyes on maintenance.