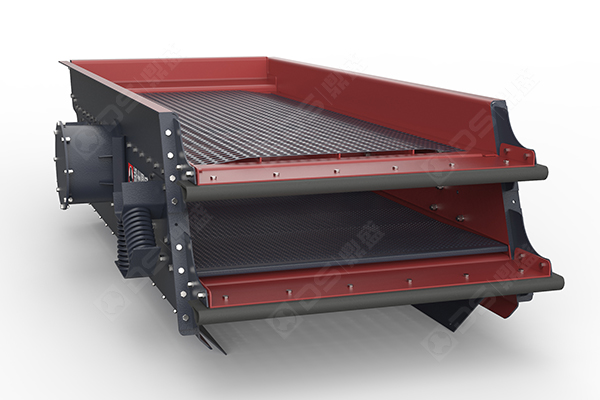

The granular shape problem is solved, then how to ensure the grading perfectly? The answer is to choose our YK SERIES VIBRATING SCREEN.

The vibrating screen has a great influence on the grading of machine-made sand. The shape and size of screen mesh, the inclination angle of the screen decks are all key factors affecting the quality of the finished machine-made sand.

Screen mesh shape: There will be a large content of stone powder particles in the process of sand production. The screen with square shape mesh is mostly used to ensure the perfect grading rather than rectangular and round shape ones.

The inclination angle of the screen decks: The screen decks angle should be controlled at about 20° to achieve a good screening effect and processing capacity of the material.

Mesh size: The mesh size of the screen directly affects the fineness modulus, grading and stone powder content of machine-made sand. The larger the size is, the greater the fineness modulus of machine-made sand is. When the mesh size is between 3.5 and 4.5, the grading, stone powder content and fineness modulus of the finished product can better meet the production requirements.

Our YK series vibrating screen adopts square mesh which can greatly improve the penetration rate of the material; the inclination angle of the vibrating screen can be adjusted between 18-25° according to the projects’ needs; the screen mesh size ranges from 2mm to 150mm. When the YK series vibrating screen is used in the production of machine-made sand, there is corresponding screen which can be directly configured to ensure the product grading.

The economical VSI impact crusher matches with high-performance YK series vibrating screen, easily producing superb quality machine-made sand!

In addition to the granular shape and grading, our VSI crusher and YK series vibrating screen also has the advantages such as controllable powder content (free adjustment between 3-15%) and controllable moisture content. The finished sand can meet various high-standard requirements.