Raw materials: River stone, pebble, iron ore, non-ferrous metal ore, corundum, bauxite, quartz sand, perlite, basalt

Capacity: 300-1500t/h

Max feeding size: 60mm

Application: Construction, mining, metallurgy, highways, railways, Bridges, water and electricity, mineral powder grinding, mechanism sand industry

Delivery: 30-45 working days

E-mail: info@dscrusher.com

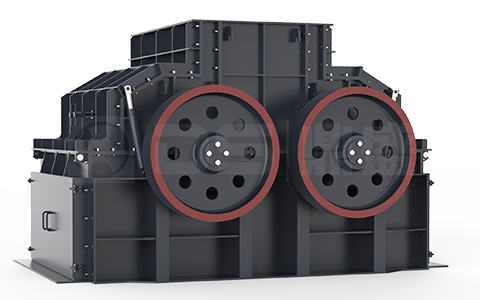

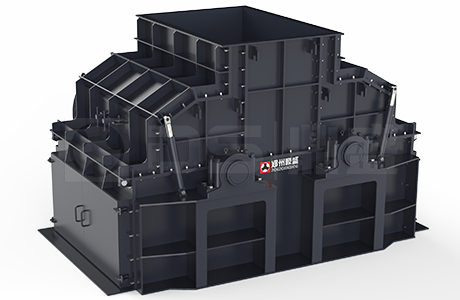

The XPCS series Dual-rotor Sand Making Machine is a new generation of sand making equipment launched by Zhengzhou Dingsheng after absorbing domestic and foreign technical advantages and based on years of production experience. The XPCS series dual-rotor sand making machine features that it can increase production, reduce power consumption and improve economic benefits effectively. The processing capacity of XPCS series double-rotor sand making machine is up to 1500 tons per hour, and finished machine-made sand can reach 750 tons per hour.

Core Advantages:

1. Integrate the advantages of hammer crusher, impact crusher and VSI crusher;

2. Adopt the optimized cavity structure to effectively use the cleavage and crushing principle of "stone hitting stone";

3. Large production capacity, fine product size, long service life of wear parts;

4. Reduced required motor power, lower power consumption, and convenient maintenance.

5. The particle size ratio can be adjusted according to user requirements.

1. Strong shaping effect;

2. Horizontal rotors arrangement;

3. Double rotors running oppositely at high speed;

4. Adopting the “Big Gold Tooth” hammers made by ceramic composite material of our patented product, which greatly prolongs the service life of each hammer;

5. Adaptable to a wide range of feed size.

| Model | Rotor diameter (mm) | Rotor width (mm) | Hammer quantity | Feed size (mm) | Product size (mm) | Capacity (t/h) | Power (kw) |

| XPCS300 | 1200 | 1800 | 48 | ≤60 | ≤5(45-50%) | 300 | 2×(160-200) |

| XPCS500 | 1400 | 1900 | 64 | 500 | 2×(250-280) | ||

| XPCS800 | 1900 | 1900 | 96 | 800 | 2×(400-450) | ||

| XPCS1000 | 1900 | 2380 | 120 | 1000 | 2×(500-560) | ||

| XPCS1600 | 2300 | 2600 | 168 | 1500 | 2×(630-710) |

Note: Any change of technical data shall not be advised additionally.