Raw materials: All kinds of sand or stone

Capacity: 150-550 t/h

Max feeding size: 700mm

Application: Heavy duty feeding and scalping of wet and sticky material in mining, aggregates, mineral processing, recycling and various industries

Delivery: 15-30 working days

E-mail: info@dscrusher.com

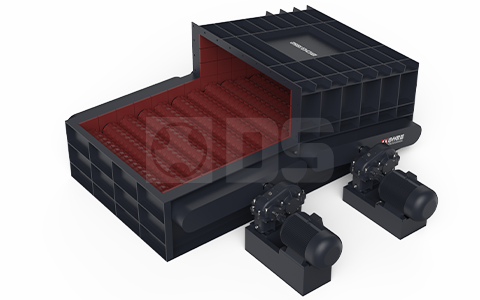

The BDG roller feeder is a combined machine, which has dual function: feeding and sieving. It is designed specially to feed the heavy crushers continuously. Owing to the front-sieving, this equipment can sieve out the desirable, fine materials, which improve the production capacity of the whole crushing system and reduce the attrition to crushers. Usually, the fine materials contain mud, and the mud may jam the crusher. So it can avoid the jam by sieving out the fine materials in advance. This machine has many rollers, it runs in the same direction, make the stone from one border. The gap between adjacent roll forming can make crushed material leakage. BDG roller feeder divided into steel hopper, feeding section and sieve section.

Engineered for heavy duty applications, BDG series roller feeder integrates scalping as material continuously feeds. The wear resistant undulated roller enables BDG series feeders processing flaky, abrasive material either in mobile or stationary installations.

1. Durability, stability

2. Scalping and feeding

3. Adjustable feed rate as option

4. Low noise and energy consumption

5. Less blockage in crusher as fines are scalped

| Model | Max Feeding Granularity (mm) | Feeding Capacity(t/h) | Power (kw) | Weight (t) |

| BDG1252 | 600 | 150-200 | 15 | 23 |

| BDG1552 | 600 | 300-400 | 22 | 27.5 |

| BDG1852 | 700 | 700-900 | 37 | 31 |

| BDG1238 | 600 | 350-450 | 18.5 | 16 |

| BDG1538 | 600 | 400-500 | 22 | 18 |

| BDG1830 | 600 | 400-550 | 37 | 13 |

| BDG2327 | 600 | 400-550 | 37 | 13 |

Note: Any change of technical data shall not be advised additionally.