Raw materials: natural sand, top soil, construction and demolition waste, limestone, granite, asphalt, sand, coal or concrete, quarry overburden, sticky aggregate etc.

Production capacity: 100-400 tph

Applications: Multistage scalping and screening in quarrying and other applications; Pre-screening/scalping; Recycling construction and demolition waste; Top soil and many other products; Separation of “sticky” aggregate.

Delivery: 30-50 working days

E-mail: info@dscrusher.com

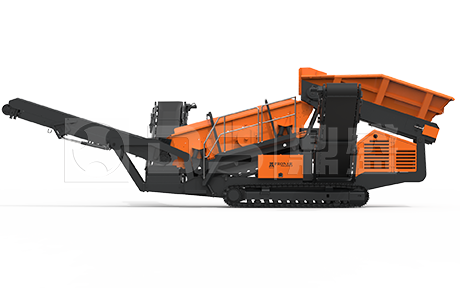

DSMAC® RC Series Mobile Scalping Screen is commonly used as primary scalper in top soil and natural sand applications. It is suitable in multistage crushing processes to split the products between the primary and secondary crusher. The material is typically fed by the excavator. The feeder lifts material to two-deck screen which then separates material to oversize and side conveyors.

RC Series Mobile Scalping Screen is a combination of extremely accurate classification of end product and high output. It is engineered for aggregate producers who demand superior productivity, versatility and reliability. Its cost effectiveness is justified by its low fuel consumption, low operating costs and maintenance as well as high capacity. With mobile scalping screen you can maximize productivity and reduce operating costs while increasing safety and reducing environmental impact which is very important nowadays. All of our screening units are operated on diesel and electricity, also referred to as hybrid.

1. Adaptable to all applications

2. Mobility, flexibility and compactness

3. Safe and easy transport

4. Robust chassis and track frame

5. Robust and wear resistant feed hopper

6. Low fuel consumption (20-40% less than hydraulic models)

7. Easy and rapid maintenance

8. High uptime and high productivity

9. Low operating costs

| Model | Screen surface area (mm) | Max. screen capacity (t/h) | Motor power (kw) | Driving type | Transporting dimension (L*W*H) (mm) | Transport weight (t) |

| RC38 | 1200 × 3500 | 250 | CAT 94 | hydraulic | 12833×2711×3518 | 25 |

| RC45 | 1800 × 4500 | 380 | CAT 94 | hydraulic | 13360×2720×3180 | 30 |

Note: Any change of technical data shall not be advised additionally.