Raw materials: granite, limestone, basalt, shale, river pebble, bluestone, sandstone, calcium carbide, iron ore, copper ore, steel slag, construction waste etc.

Production capacity: 100-400 t/h

Applications: crushing and screening application in mining, aggregates, mineral processing, and recycling construction and demolition waste

Delivery: 30-50 working days

E-mail: info@dscrusher.com

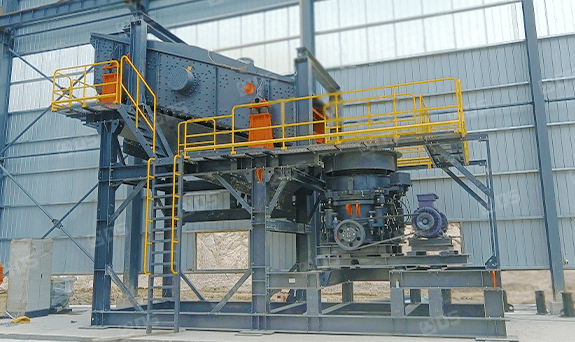

Modular Crushing and Screening Plant is designed for large quarries or contractors that want a stationary type design without the complexity of a normal stick-built plant. The modular structure can be transported in standard shipping containers plus a flat rack for the crusher and can be bolted together quickly on site with basic tools.

These modular equipment can become a complete solutions quickly, giving you optimized process performance and controlled budget and delivery time for the best return on your investment.

A selection of modules and layouts is available for primary, secondary, tertiary and quaternary crushing and screening. Designed for versatility, the modular range is scalable to fit your present and future production needs.

Dingsheng offers more than 20 pre-designed and ready-to-run modular equipment with capacities up to 400 tph for quick production start-up. Whether you are looking for an easy or complex plant, one crushing stage or three crushing stages, you can always find a suitable configuration for your needs here.

Increase aggregates production capacity and/or quality in an existing plant, by adding a new line

Re-crush and valorize coarse unsold fractions

Produce additional fractions, when needed, based on seasons or end customers' needs

| Model | Max. feed size (mm) | Capacity (t/h) | Installed power (kw) | Generator set (kw) | Overall dimension (L*W*H) (mm) |

| Customized | Customized | Customized | Customized | Customized | Customized |

Note: Any change of technical data shall not be advised additionally.