Raw materials: Granite, limestone, basalt, shale, pebbles, bluestone, sandstone, carbide, iron ore, copper ore, steel slag, manganese ore, andesite, quartz, silica, gypsum, volcanic rock, marble, river stone, gravel, coal etc..

Capacity: 100-2000 t/h

Max feeding size: 1500*2000mm

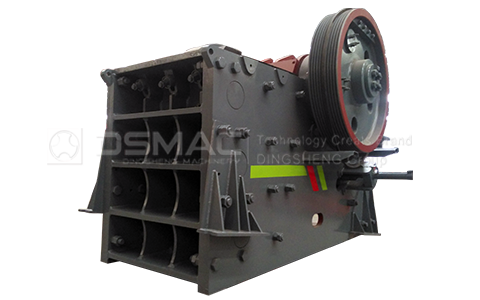

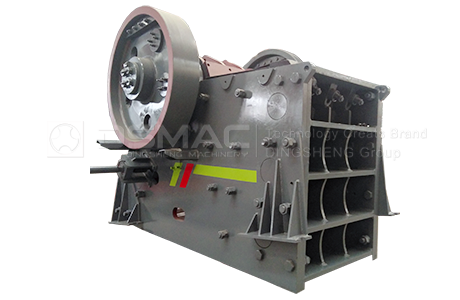

Application: Primary crushing applications in extreme hard material condition in mining, quarrying, industrial mineral processing, and recycling reinforced concrete

Delivery: 15-30 working days

E-mail: info@dscrusher.com

The JC Series Jaw Crusher is built in line with the most advanced Austrian style crusher technology. With bolted construction, the outstanding design provides the toughest fatigue strength and easy to be transported.

The steep cavity boosts the reduction ratio of the feed materials. The JC series jaw crusher are proven for the toughest material condition in various application.

1. Increased intake capacity

2. High uptime

3. Space saving

4. High reduction ratio

5. Less and simple maintenance

6. The starry sky TM superior metallic ceramic jaw plates prolong the spares service life by 50% to 80% thereby reducing the production costs.

| Model | Capacity (t/h) | Outlet size (mm) | Inlet size (mm) | Power (kw) | Weight (t) |

JC900 | 100-250 | 60-175 | 600x900 | 90 | 12.8 |

| JC1100 | 150-450 | 70-200 | 760x1100 | 132 | 23.8 |

| JC1200 | 250-600 | 150-300 | 900x1200 | 160 | 44 |

| JC1400 | 350-800 | 160-350 | 1100x1400 | 200 | 63 |

| JC1600 | 500-1000 | 200-400 | 1200x1600 | 250 | 83 |

| JC2000 | 600-2000 | 250-450 | 1500x2000 | 400 | 140 |

Note: Any change of technical data shall not be advised additionally.