Raw materials: Limestone, siltstone, shale, gypsum, coal, coal gangue

Capacity: 80-2000t/h

Max feeding size: 1500mm

Application: Special cement crusher, large scale sandstone aggregate production line project, beneficiation equipment

Delivery: 15-30 working days

E-mail: info@dscrusher.com

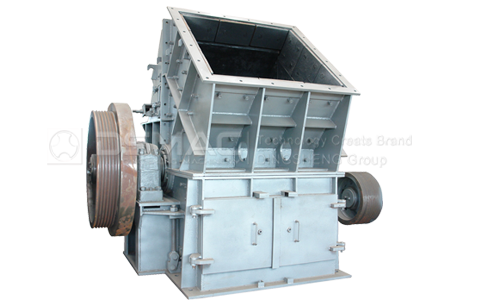

The proven and reliable DPC series hammer crusher is a cost-effective solution for processing abrasive and moderately sticky raw materials in one stage.

It is mainly suitable for crushing various ores the compressive strength of which is no more than 150MPa.

1. High Performance - Low Operating Costs

a. Capacity increased by 5-10% and up to 2500 tph, China largest scale single stage hammer crusher;

b. Longer service life of wear resistant parts. The AMC alloy hammerhead (Big Gold Teeth®) service can be increased by 50~150%;

c. The new hammer rotor consists of heavy, forged, square cross-section shaft fitted with cast steel rotor discs. The special "sandwich" assembly of the discs is a robust construction, preventing distortion and crack formation.

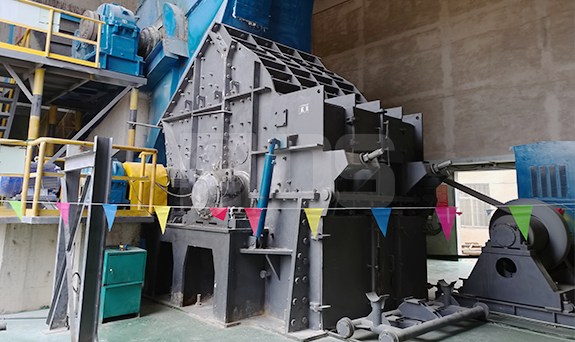

2. Hydraulic opening of crusher housing

Another feature is the hydraulic opening of the crusher cavity which reduces downtime and makes servicing of the crusher safer. Installing two hydraulic cylinders, appertaining brackets and a set of hinges enable the crusher to be opened within 5 - 10 minutes.

3. Hydraulic tool for changing the hammers

A hollow hydraulic cylinder placed in a rigid frame is provided to handle the hammer bolts when turning or changing hammers. Mobile hydraulic power unit supplies the hydraulic pressure to operate the cylinder.

4. Controlling the Final Product

The outlet grate is equipped with sturdy and replaceable grate bars supported by heavy cheeks. The position of the outlet grate assembly can be adjusted to control the final product. This takes place hydraulically from outside the crusher casing.

| Model | Rotor Size (mm) | Capacity (t/h) | Hammers Quantity | Inlet size (mm) | Max. feeding size (mm) | Product size (mm) | Power (kw) |

| DPC1412 | Φ1420×1194 | 80-150 | 28 | 1290×1320 | 500×500×900 | 90%≤25 | 200 |

| DPC1616 | Φ1650×1630 | 150-220 | 32 | 1500×1785 | 800×800×1200 | 90%≤25 | 315 |

| DPC1818 | Φ1850×1800 | 300-400 | 40 | 1755×1780 | 1000×1000×1000 | 90%≤25 | 560 |

| DPC2018 | Φ2018×1802 | 350-500 | 40 | 2040×1860 | 1000×1000×1000 | 90%≤25 | 710 |

| DPC2022 | Φ2018×2227 | 400-600 | 50 | 2228×2460 | 1000×1000×1200 | 90%≤25 | 800 |

| DLPC2022-1 | Φ2018×2227 | 600-800 | 50 | 2228×2460 | 1000×1000×1500 | 90%≤25 | 800 |

| DLPC2022-2 | Φ2018×2227 | 700-900 | 50 | 2228×2460 | 1000×1000×1500 | 90%≤25 | 800 |

| DPC2325-1 | Φ2300×2500 | 800-1000 | 66 | 2330×2690 | 1100×1200×1500 | 90%≤75 | 1120 |

| 2DPC1818 | Φ1850×1890 | 800-1000 | 40×2 | 2030×2080 | 1000×1000×1200 | 90%≤75 | 560×2 |

| 2DPC2022 | Φ2018×2237 | 1200-1500 | 50×2 | 2670×2460 | 1000×1200×1500 | 90%≤75 | 800×2 |

| 2DPC2325 | Φ2300×2508 | 1600-2000 | 66×2 | 3065×2666 | 1100×1200×1500 | 90%≤75 | 1120×2 |

Note: Any change of technical data shall not be advised additionally.