Raw materials: Limestone, cement clinker, calcium carbide, coal

Capacity: 10-2000t/h

Max feeding size: 500mm

Application: clinker crushing and fine crushing, soft rock manufactured sand

Delivery: 15-30 working days

E-mail: info@dscrusher.com

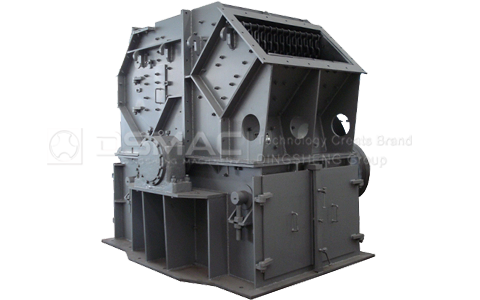

DSMAC has successfully designed and manufactured the newest high efficiency fine crusher. It is mainly used for fine crushing of dinas, sand making, and for crushing in cement factory, etc.

The signature patented HIS hammer mill integrates the rock-on-rock and rock-on-iron principles into one unit. The fed material gets crushed as it enters the crush chamber and later the crushed portion twists and grinds with each other internally and discharges fines through the grid plate.

1. Most economic solution to clinker crushing and grinding

2. High efficiency sand manufacturing application up to 1500 tph throughput rate and 750 tph sand

3. 30 to 50% less power rating

4. 3 to 4 times hammer service life thanks to our SandwichTM hammer

| Model | Rotor size (mm) | Capacity (t/h) | Max. feed size (mm) | Product size (mm) | Power (kw) |

| XPCF20 | Φ800x400 | 10-20 | 120 | 4 | 30-37 |

| XPCF30 | Φ800x600 | 20-30 | 37-45 | ||

| XPCF40 | Φ900x600 | 20-40 | 150 | 5 | 37-45 |

| XPCF50 | Φ900x700 | 30-50 | 45-55 | ||

| XPCF60 | Φ900x900 | 40-60 | 55-75 | ||

| XPCF70 | Φ1000x950 | 40-70 | 200 | 6 | 55-75 |

| XPCF80 | Φ1000x1100 | 50-80 | 75-90 | ||

| XPCF90 | Φ1000x1250 | 60-90 | 90-110 | ||

| XPCF100 | Φ1250x1100 | 50-100 | 250 | 8 | 90-110 |

| XPCF125 | Φ1250x1350 | 80-120 | 110-132 | ||

| XPCF150 | Φ1250x1650 | 100-150 | 160-200 | ||

| XPCF200 | Φ1600x1350 | 100-200 | 300 | 10 | 160-220 |

| XPCF250 | Φ1600x1650 | 150-250 | 220-250 | ||

| XPCF300 | Φ1800x1800 | 150-300 | 350 | 12 | 315-355 |

| XPCF400 | Φ1800x2200 | 200-400 | 400-450 | ||

| XPCF600 | Φ2200x2600 | 400-600 | 560-630 | ||

| XPCF1000 | Φ2400x2800 | 600-800 | 630-710 | ||

| XPCF1500 | Φ2600x3000 | 800-1000 | 500 | 800 | |

| XPCF2000 | 2Φ2600x3000 | 1500-2000 | 2*800 |

Note: Any change of technical data shall not be advised additionally.